E-RETICLE

The E-Reticle makes in-situ-measurement of electrostatic charges on photomasks during production possible. For the first time, we have integrated measuring devices into a product that is able to move through the production process.

The lifespan of photomasks is limited. One factor that reduces this lifespan is the effect of electrostatic discharges within the mask. The mixture of floating conductive chrome areas and highly insulating quartz glass on the masks surface provides perfect conditions for electrostatic charges to form – e.g. during the production of the mask itself or while it is used in the wafer production process. Moving parts in a machine, friction, or other factors can cause an electrical potential drop between the different chrome areas, leading to an electrostatic discharge. It is possible for the discharge to immediately destroy the chrome areas. However, more commonly these discharges lead to barely noticeable damages which – by corrosion, mechanical stress, or further discharges - will destroy the chrome areas over time.

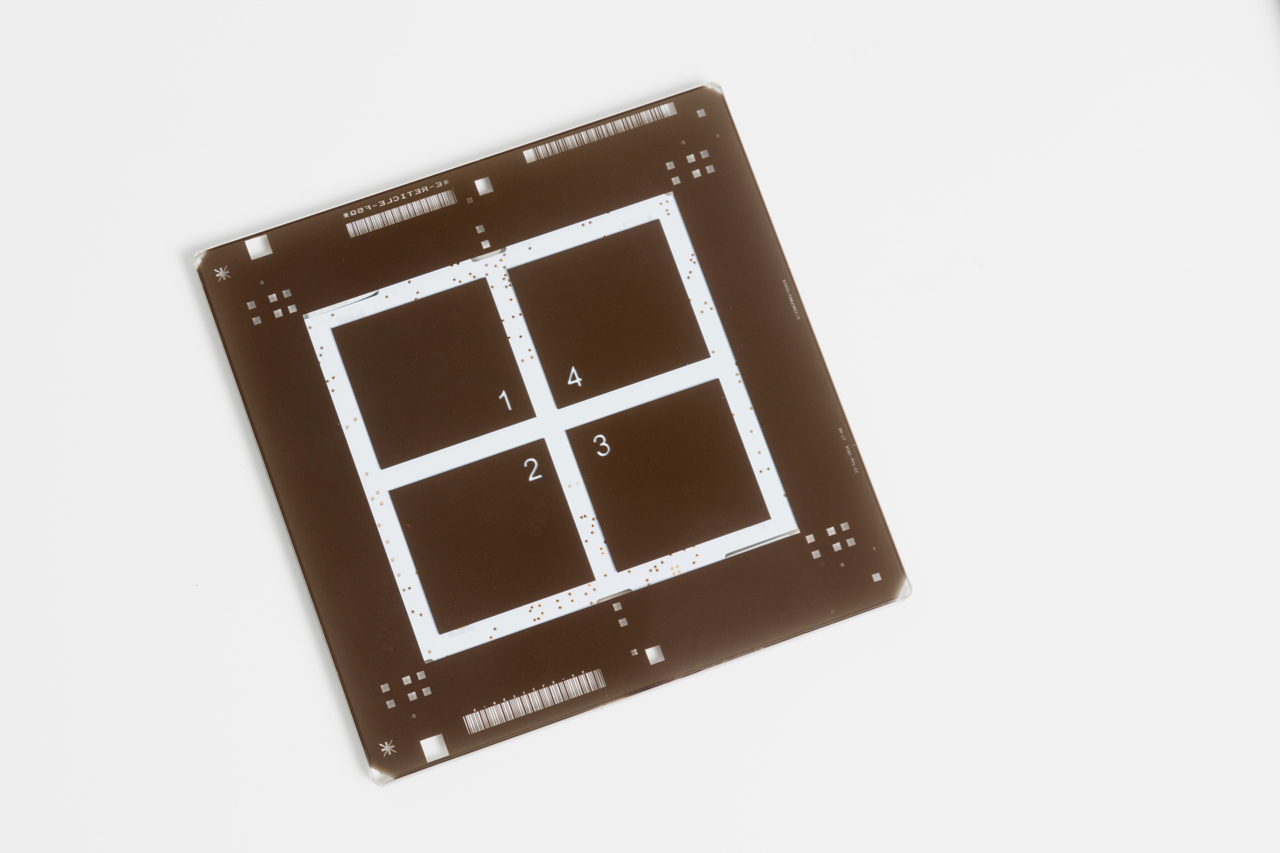

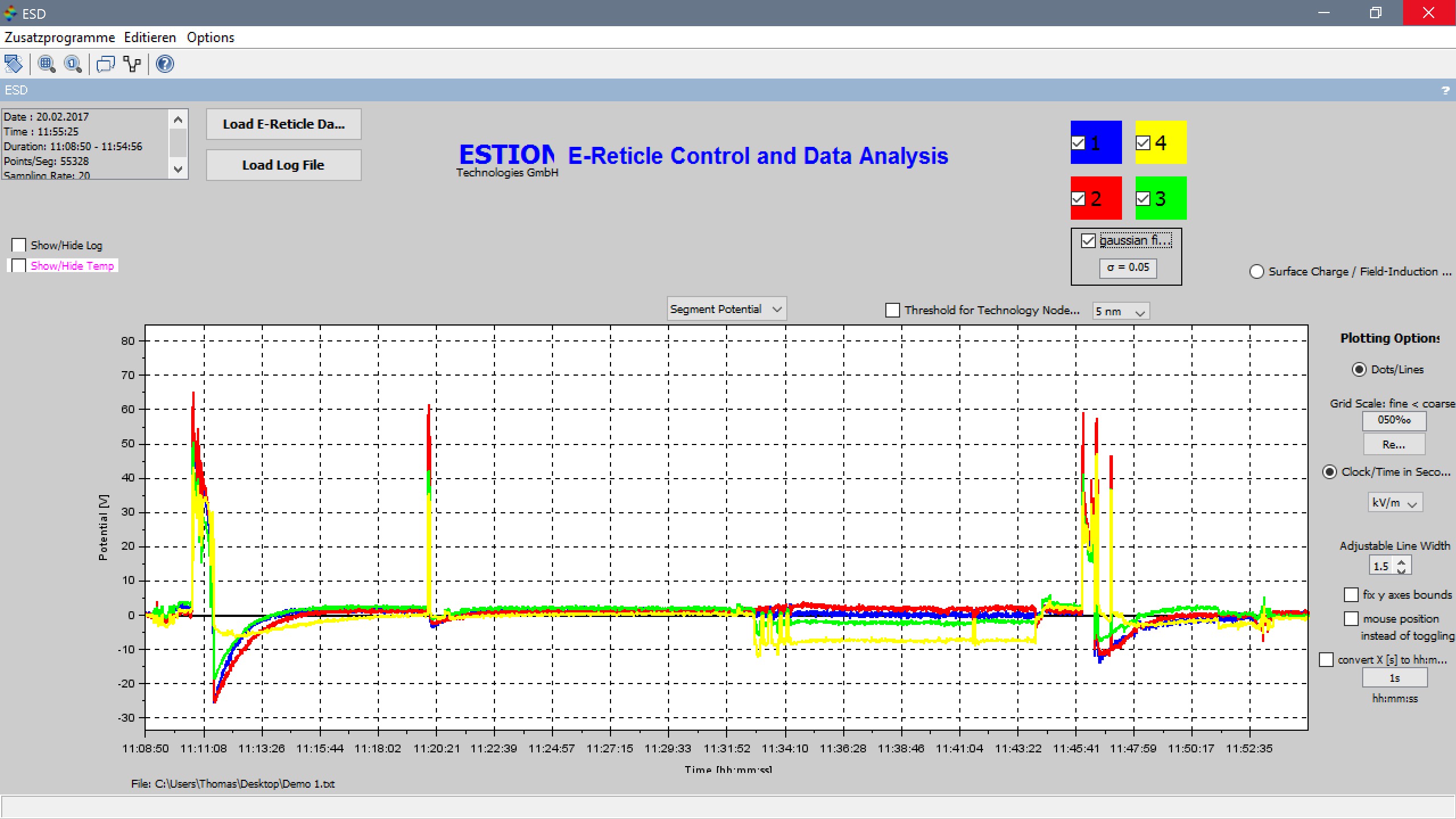

The E-Reticle is the first system to provide in-situ measurements of electrostatic charges on the mask's surface throughout the entire production process. It measures the potential difference of four separate areas related to an outer ring on the mask's surface. This means it measures exactly those areas of the photomask that are at risk of an electrostatic discharge to occur. With an integrated real-time clock, memory, WLAN connection, and the provided software, it is easy to analyze the production process and pinpoint exactly where critical electrical potential differences occur.

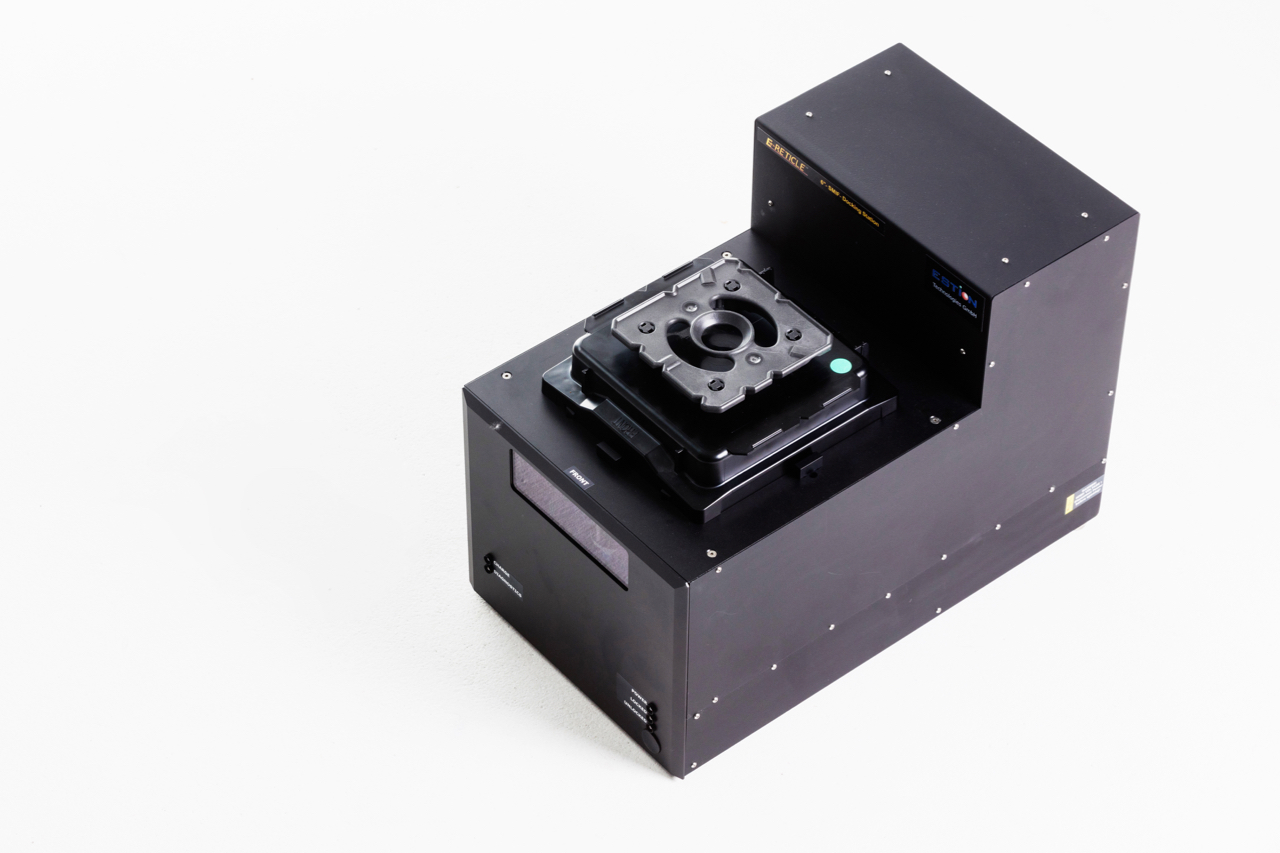

The E-Reticle is designed for routinely controlling the production process with regard to electrostatic problems. It is housed in a Reticle SMIF-compatible docking station, allowing it to be integrated into automated processes. This way, it can easily measure all steps a real photomask would undergo regularly.

For use as a risk-analyzer in engineering or R&D, the E-Reticle is available in a portable docking station as well.

Contact us for further information! We are happy to make up an individual quote for you.